Table of Contents

Resin sculpture/transparent resin sculpture production process

- Drawing (3D modeling or CAD dimension drawing)

- 3D printing resin mold species

- Open silicone mold

- Grouting production

- Repair and sanding

- Spray primer

- Coloring (spray paint, color painting, electroplating, spray plating, flocking, water transfer printing, etc.)

Customized fiberglass sculpture production process

- Drawing (3D modeling or CAD size drawing)

- Carve foam draft

- turn the plaster mold

- Turning fiberglass mold

- Patching and polishing

- Spray primer

- Coloring (painting, color painting, electroplating, spray plating, flocking, water transfer printing, etc.)

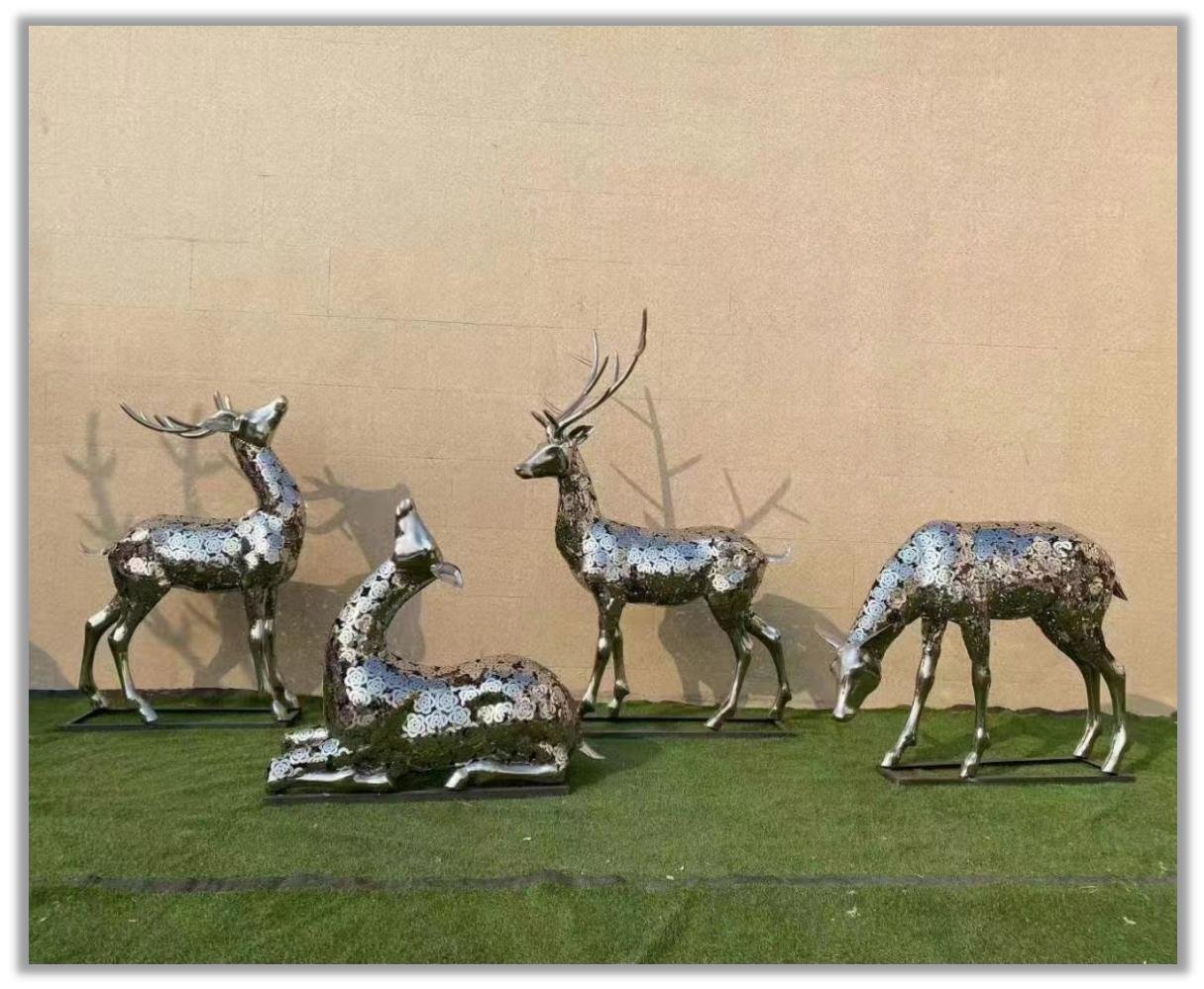

Forged stainless steel / metal sculpture production process

- Drawing (3D modeling or CAD dimension drawing)

- sculpture foam draft

- Hand forging stainless steel/metal

- Welding combination

- Sanding and polishing

- Spray primer

- Coloring (painting, lacquering, electroplating, spraying, flocking, water transfer, etc.)

Wooden sculpture production process

- Drawing (3D modeling or CAD dimension drawing)

- machine carving wood

- manual repair and sanding

- spray primer

- coloring (spray paint, color painting, water transfer printing, etc.)

Acrylic sculpture production process

- drawings (3D modeling or CAD dimensional drawings, acrylic needs to be out of the decomposition diagram)

- slicing

- combination

- spray painting